Watch the Inbound Receiving stage of our tire retread plant tour.

The old tread is mechanically buffed away to the proper radius and diameter.

Watch the Buffing Stage of our tire retread plant tour.

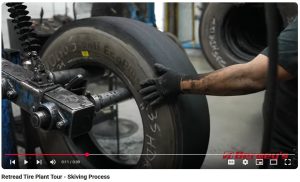

Watch the Skiving Process of our tire retread plant tour.

Watch the Tread Building stage of our tire retread plant tour.

Once the tread is applied, the completed tire is put into a curing envelope encasing the interior and exterior of the tire to set it up for the vulcanizing chamber.

Watch the Tire Envelope stage of our tire retread plant tour.

Watch the Vulcanizing stage of our tire retread plant tour.

Watch the Final Inspection and Testing stage of our tire retread plant tour.

Watch the Inbound Receiving stage of our tire retread plant tour.

E

Watch the Initial Inspection stage of our tire retread plant tour.

The old trea

Watch the Buffing Stage of our tire retread plant tour.

Watch the Skiving Process of our tire retread plant tour.

Watch the Repairs and Extrusion stage of our tire retread plant tour.

Watch the Tread Building stage of our tire retread plant tour.

Watch the Tire Envelope stage of our tire retread plant tour.

Watch the Vulcanizing stage of our tire retread plant tour.

Watch the Final Inspection and Testing stage of our tire retread plant tour.